Cast Iron Cookware Manufacturers

CAST IRON COOKWARE MANUFACTURERS

Some Brief Histories and Information on Cast Iron Cookware Manufacturers

(Past and Present)

Cast Iron has long been utilized in the manufacture of cookware due to its durability and ability to retain its heat when used with lower temperature heat sources.

Known as Hollow Ware, this cookware was produced by a pouring molten iron (Cast Iron) into a mold prepared from an iron or brass pattern. Cast Iron was preferred for cooking, and after turning on a lathe, was coated with tin. This method was patented by Jonathan Taylor, a Birmingham (England) workman, in 1779.

“Since the introduction of these methods of protecting and beautifying the surface of iron, domestic vessels of this metal have greatly taken the place of those made from copper and brass.”

The Enameling of cast iron dates as far back as a 1779 patent and a subsequent patent in 1839 by Messrs T. and C. Clark of Wolver Hampton (England), which improved on the process. The difficulties in enameling cast iron were due to the expansion rate difference between the iron and the vitreous enamel coating, but this has subsequently been overcome.

With respect to the use / manufacture of Cast Iron Cookware in the US, the following is interesting to note:

“English hollow-ware is Bent to most civilized countries, but for export trade the best markets are found in the British colonies. Little or none is taken by France and scarcely any by the United States since the outbreak of the civil war, on account of the high duties.”

Also interesting to note:

“A great deal of cast-iron tinned hollowware is now made without being turned, an omission easily detected by the uneven surface which the inside of such vessels presents.”

Stuart, Peterson & Co.’s

One notable US manufacturer of Hollow Ware was the Spring Garden Stove & Hollow Ware Works owned by the Stuart, Peterson & Co.’s Foundry est. 1844 in Philadelphia. By utilizing an automated lathing process, they improved on the hand lathing process employed in England in addition to improving the tinning and enameling processes in use at the time.

Domestic manufacturers such as the Griswold (est. 1865) and the Wagner (est. 1881) at one time used to Lathe, or turn, their cookware but this practice is generally not employed anymore due to manufacturing costs, and the cookware is seasoned with oil and not tinned.

Griswold History

Matthew Griswold and the Seldon brothers started the Seldon-Griswold Manufacturing Company in 1865, manufacturing separable butt hinges and other articles of light hardware. They worked in a building know as the “Butt Factory” on West 10th and Chestnut Streets, on the bank of the Erie Extension Canal in Erie, PA. In the 1870’s, the added cast iron cookware items, such as pots, skillets, and griddles to their line of products.

In 1884, Mathew Griswold who was heading up the company bought out the Seldon’s and formed the Griswold Manufacturing Company and over the next 3 years rounded out their cookware offerings with Kettles, Dutch Ovens, Roasters, and various pots and pans. In 1889, Griswold started the aluminum cookware era by casting aluminum for cookware which became popular due to it’s light weight, and with their reputation for manufacturing the finest cast iron cookware at the time became a leading supplier of aluminum cookware as well.

In 1957, Griswold officialy closed it’s doors after decades of producing a variety cast cookware and other items. Their pieces remain as highly collectable to this day since their unique markings allow them to be dated easily.

More Info: Cowtown Collectables.

The Lodge Manufacturing Company

Blacklock Foundry was established in 1896 by Joseph Lodge in South Pittsburg (ironic), Tennessee and today remains one of America’s oldest cast iron cookware manufacturers still in operation. In 1910, the foundry burned down, and after rebuilding was incorporated as the Lodge Manufacturing Company whose line included holloware, kettles, pots, vents, sad irons (for ironing clothing), andirons, and fireplace grates and fenders.

Lodge is still in business today making cast iron cookware like griddles, skillets, dutch ovens and baking pans.

Please visit their website at www.lodgemfg.com for further information.

Wagner History

The Wagner Manufacturing Company was founded in 1891 by Milton and Bervard Wagner manufacturing cast iron hollow ware and nickel plated ware in Sidney, Ohio.

Although manufacturing a wide range of products, cookware became their claim to fame and they vrtually pioneered the cast aluminum cookware industry in 1894 winning numerous awards internationaly. According to a 1998 article from the Shelby County Historical Society, Wagner was then the oldest continuously operating manufacturer of cookware in the country.

Wagner was acquired by The Randall Company of Cincinnati, Ohio in 1953 and acquired the Griswold line of cookware in 1957. Randall itself was acquired by Textron in 1959, followed by General Housewares in 1969. A group of investors known as The Wagner Corporation bought the Wagner factory in 1997 and closed it in 1999. The plant finally reopened in 2003 and started to produce iron cooking items.

LE CREUSET

Le Creuset began in 1925 in Fresnoy-le-Grand, France, a route for iron, coke, and sand, when Armand Desaegher, a casting specialist, and Octave Aubecq, an enameling expert, recognized and set out to improve the versatility of cast iron cookware by coating it in a porcelain enamel glaze. That same year, the first cocotte, or French oven, was produced, laying the foundation for what is now an extensive range of cookware and kitchen utensils. Le Creuset’s signature color was Flame, and modeled after the color of the intense orange hue of molten cast iron inside a cauldron (“creuset” in French).

The United States subsidiary was begun in South Carolina in 1974.

References and Quotes:

1) Chambers Encyclopedia, Vol. X., W. & R. Chambers, Edinburgh, 1869

2) A History of American Manufacturers from 1608 to 1860, Edward Young and Company, Philadelphia, 1868

3) Hexamer General Surveys, Volume 9, Ernest Hexamer

NEW BOYS IN TOWN

Cast Iron has an enormous appeal for a lot of folks these days and a number of new manufacturers are providing items with new technologies aimed at replicating the finest of the hand crafted vintage items produced years ago. Weight, smoothness and just a good solid product that one day may be vintage is the goal. Check them out.

STARGAZER CAST IRON

Newcomer to the cast iron manufacturers list. The goal was to recreate some of the weight and size features of vintage cast iron cookware such as the aforementioned Griswold and Wagner items. What’s interesting is the are milling the surface of the pan to give it a smooth surface for cooking. They’re just starting off and offering their product via kickstarter. Also of note, these are available as pre-seasoned or non seasoned pans which is desirable for a lot of collectors. Check out their video for more details. Stargazer Cast Iron Pans. The kickstarter is here: Startgazer kickstarter.

SOLIDTEKNICS

SOLIDTEKNICS is an Australian manufacturer of cast iron and steel cookware available for domestic sales in the US. Also dedicated to a smooth cooking surface which delights many cast iron cooks.

FROM THEIR WEBSITE

“SOLIDTEKNICS makes two ranges of cookware: AUSfonte™ cast iron and AUS-ION™ formed-iron (steel). Both are 100% made in Australia from Australian materials, both are multi-century durable, pre-seasoned bare iron for natural, non-toxic, forever-renewable nonstick. These are not disposable synthetic-coated pans.”

They have a variety of cookware ranging from skillets, to griddles, to Dutch ovens. And they are available on Amazon here SolidTeknics.

FINEX

Finex is a Portland, Oregon producer of cast iron cookware. Started by a group of perfectionists, the have products that are at once unique in terms of what we think of as traditional cast iron but with and eye to vintage design, which takes into account weight and finish on the iron. The distinct shape and handle add to the uniqueness of their products. Individual pieces as well as sets are available on their site as well as retailers across the country. You can visit them at their website Finexusa.com for more information.

BOROUGH FURNACE

Borough Furnace, located in Syracuse, NY is really distinct as they hand make their cookware to order. They burn waste vegetable oil to heat the recycled iron for their cookware. Although they have a limited number of products they make, the basics are covered. They even have a couple of bottle openers to boot. Definitely worth a look if you want something that’s not mass produced. Check the about us page for some nice pictures and more info. Visit them here at boroughfurnace.com.

Field Company

They’re still in kickstarter mode. More info to follow.

Marquette Castings

Marquette Castings is another Kickstarter project aimed at returning cast iron cookware to it’s vintage era, but manufactured in a modern world. Some of the finest vintage cookware took a lot of consideration into both weight and product finish no longer available from current manufacturers. They are accepting pre-orders so you might want to check their Kickstarter page https://www.kickstarter.com/projects/innovative-cast-iron/marquette-castings-superior-cast-iron-skillets . Looks like they’re off to a great start.

Smithey Ironware

Smithey Ironware is a North Carolina outfit selling handcrafted cast iron cookware. They take rough iron cast pans designed to reduce the weight of the pan and hand mill it in the old fashioned way. You can check them out here. Smithey Ironware. Also a good article here.

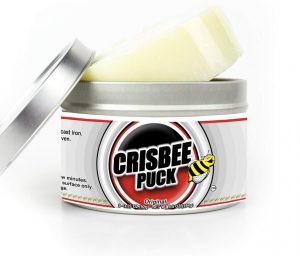

Seasoning Your New Cast Iron

Kick start that new pan. Bring life back to that vintage pan. Touch up your current collection. No matter what kind of cast iron you have, this is a must have product. There’s nothing else like it (See Our Review) for keeping that pan in shape. Go get it from Amazon now.